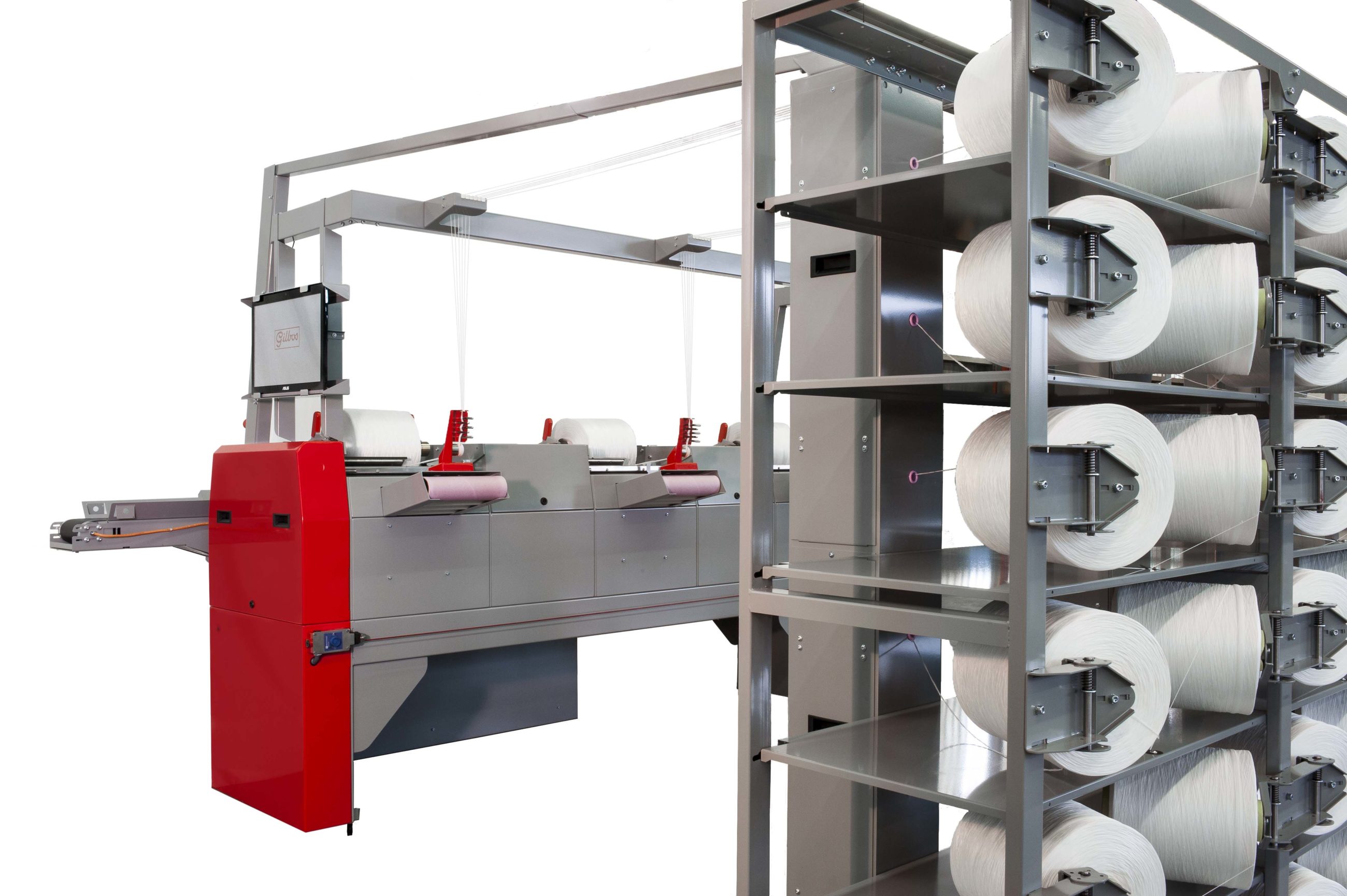

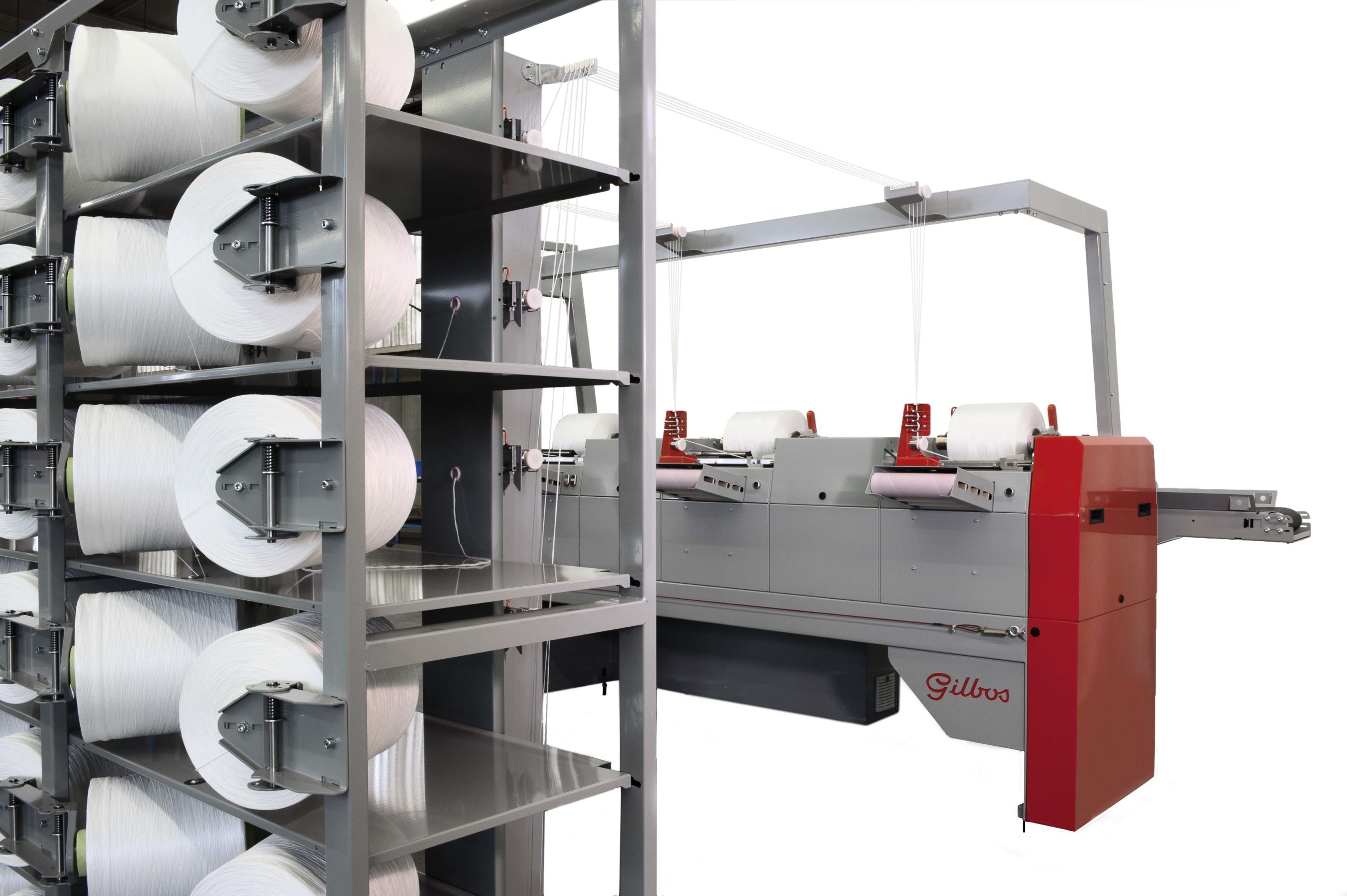

UniWinder – D

Assembly winder for filament and spun yarns.

Advantages

- Each spindle is Independent or can be grouped.

- Assembling from packages and spinning bobbins.

- Custom made creels up to 20 ends.

- Automatic doffing reduces the necessary labor force to a minimum.

- Low maintenance cost.

- Robust design with few moving parts and integrated maintenance interface allow for optimal uptime of the machine at a minimum cost.

- Flexible, modular construction.

Description

Assembly winder for filament and spun yarns.

- Assembling up to 20 ends at high speed and without any length difference.

- High efficiency thanks to a very effective automatic doffing system.

- Low maintenance cost.

- Plc controlled with an excellent operator & maintenance interface.

- Modular design with three Independent spindles per section.

Technical specifications

| Material | Filament or spun yarns – Synthetic or natural fibres |

| Yarn count | 600 to 20.000 dTex |

| Layout | 800 or 1000 mm |

| Number of positions | 3 to 24 per machine |

| Speed | up to 1000 m/min. |

| Number of ends | 2 to 20 |